Cotton Club

is the leading manufacturer of cotton products and hygiene products with own production facilities in the Russian FederationThe industrial warehouse facility

, located in Balashikha district, Moscow region, consists of several shops with a total area of more than 47,000 m²:- Cotton processing and nonwoven fabric shop

- Non-woven viscose and polyester fibers production shop

- Wet wipes production shop

- Cotton wool production shop

- LMC and cosmetic products manufacturing shop

- Cotton tape production shop

- Extrusion materials manufacturing shop

- Baby disposable panties and diapers shop

- Towel converting and food packaging shop

- Warehouse space

- Logistic complex

One of the key advantages of Cotton Club is a vertically integrated production that makes it possible to fully control the manufacturing process of both semi-finished products (sliver, sticks, lotions, non-woven fabric) and finished products.

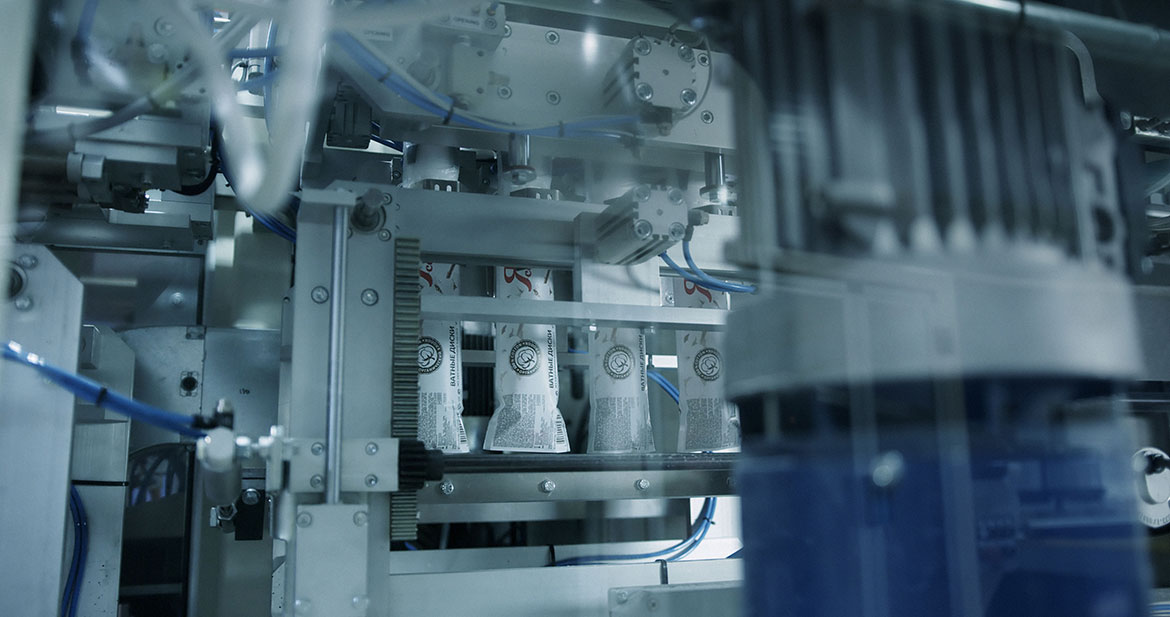

Cotton wool production

Cotton Club produces cotton wool from raw cotton. Water Jet technology is used for the production of cotton wools, thanks to which the pads have a smooth surface, don’t exfoliate and don’t shed.

Equipment for the production of cotton tape by Marzoli (Italy) is used in the production of own sliver.

In order to create a complete cycle of production of cotton swabs, the production of plastic sticks (equipment by Bellaform, Germany) and glasses (thermoplastic automatic machine by TOYO, Japan)

Polyethylene bags for cotton pads and buds are made on the leading European equipment (Hetler, Lemo).

Wet wipe production

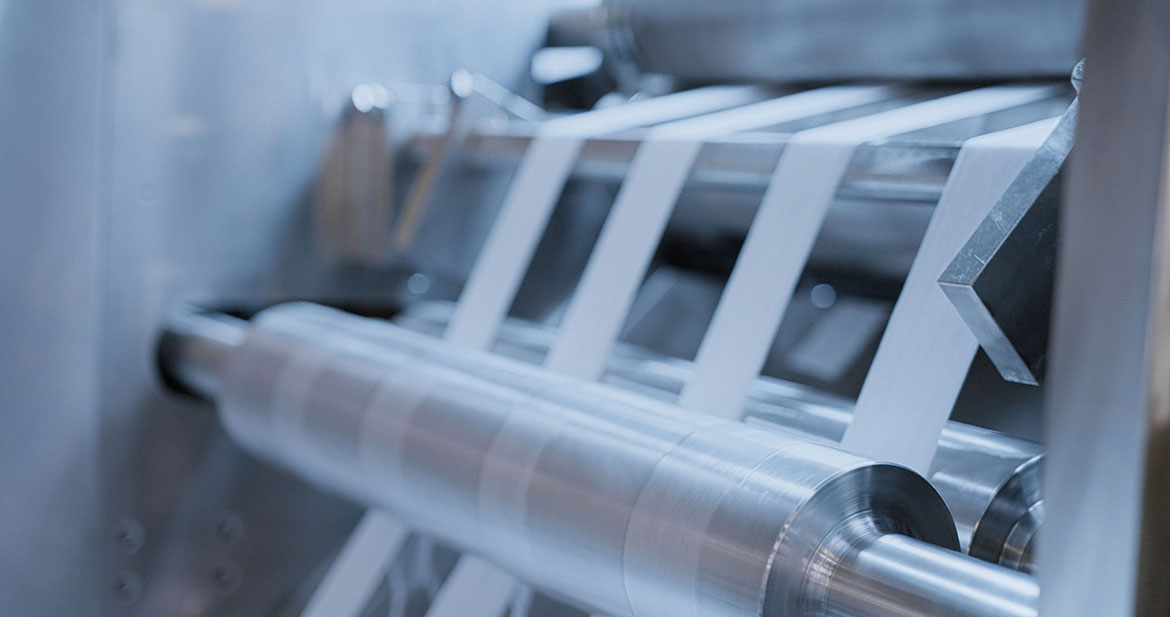

Nonwoven cloth for wipes is produced on European equipment Andritz.

The unique technology used in the company makes it possible to produce 2 types of cloth: MD:CD (MD-material direction to CD-cross direction 1:1 - the material stretches uniformly in all directions).

Wet wipes are available in various packaging formats: pocket, big, flip-top, duo-pack, trio-pack.

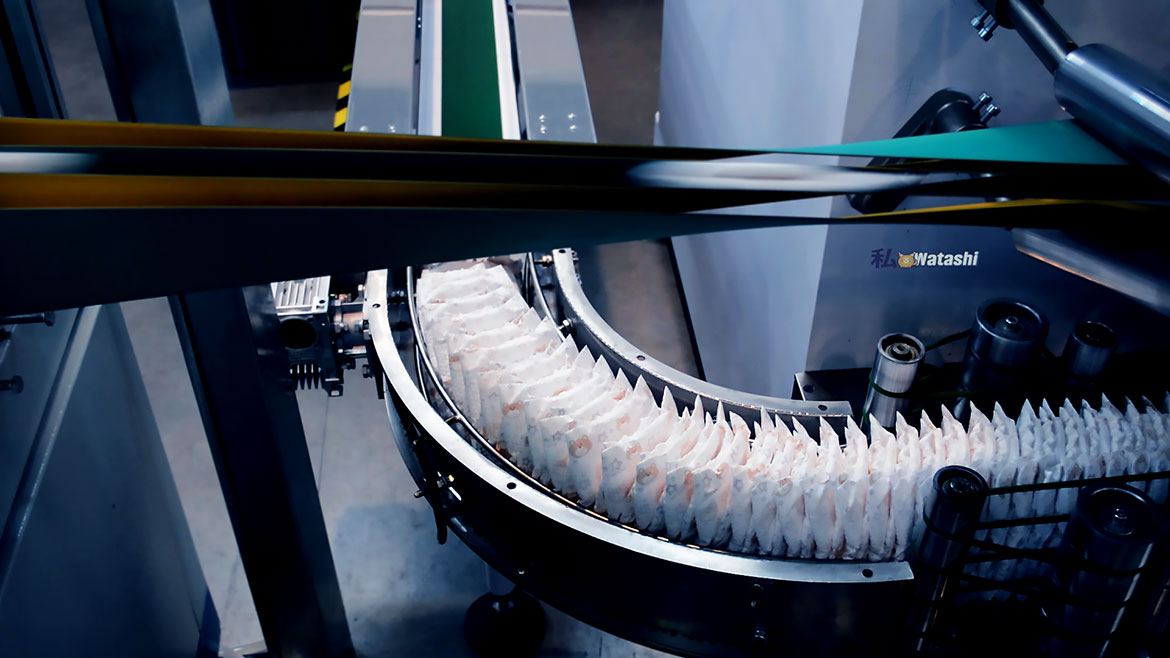

Diaper production

Thanks to three of its own machines, Cotton Club has the ability to produce three types of diapers: anatomical shape (I shape), classical (T shape), disposable panties.

The production of all layers of the diaper: top sheet, back sheet, ADL, medium absorbent layer, as well as non-woven material for the ears and cuffs, also takes place at its own capacities.

Possibilities for the types of absorbent layer of the diaper: cellulose + SAP or innovative development, a cellulose absorbent layer consisting of Air prooff + SAP pillow, which has no analogs in Russia and Europe.

Unique patented materials are used: Icore, Iproof, 3D wavelron, Doublecore.

Packaging line allows you to pack from 1-3 pieces to 88 diapers, which opens up great opportunities for the company and its customers.

Liquid detergent production

Cotton Club Group has equipment for the preparation of cosmetic mass (creams, gels, lotions, milk, scrubs, etc.), as well as its packaging: laminated tubes for creams, blowing out bottles from PET preforms, laminating stand-up pouches.

The dispensing shop can dispense and label products in different types of packaging: tubes, cans, bottles and stand-up pouches.

Production lines for working with cosmetic products were developed and produced by Urlinski, a European company.

Household products

Cotton Club independently carries out converting of foil, film, parchment, and also packs finished goods in film or in a cardboard box.

The production of garbage bags is carried out by extrusion and coloring of high and low pressure polyethylene. The company produces packages with different types of bottoms: star, straight, side seam; and formats: standard, with puffs, large, t-shirt bag.