According to Nielsen

Leader

in the market

According to Nielsen

Leader in the market

According to Nielsen, the Cotton Club Group is the undisputed leader in the market for cotton wool and wet wipes, accounting for 62% and 40% of the market share, respectively.

Cotton Club closely follows the world trends and innovations in the production of cosmetics and hygiene products.

The Company managed to achieve such success not only thanks to affordable price, but also by the quality of our products, being highly competitive with products of well-known world’s leading brands.

Thanks to cooperation with leading producers of raw materials, our own R&D laboratory develops unique means for body and hair care, the quality of which is confirmed by European GMP and ISO 9001 (GOST ISO 9001-2011) certificates.

24years

Following the current market trends, Cotton Club actively develops the Private Label area. Today, the Company’s portfolio consists of more than 70 private label manufacturing contracts for retail and pharmacy chains.

The development strategy of Cotton Club provides for continued investment in innovative projects and increased market representation.

warehouse facility

47

K m²

The company has its own industrial warehouse facility (IWF) located in Balashikha district of Moscow region, with a total area of more than 47,000 m², which together with the unique technologies for storing in the distribution center with an increased capacity make the supply of finished products match the needs of customers.

Vertically

integrated

production

A key competitive advantage of the Cotton Club Group is its vertically integrated production, which makes it possible to fully control the production process.

That, in turn, provides for a quick response to market changes, ensuring a dual control - in the production of semi-finished products (sliver, sticks, lotions, non-woven material) and in the production of finished products.

Cotton Club

holds patents for unique inventions in the area of materials and equipment.

Icore

unique multi-layer composite absorbent for use in the hygiene industry.

Iproof

lightweight non-woven fabric that distributes the superabsorbent throughout the entire volume thanks to its unique porous structure.

Among the partners of the Company are the top manufacturers of equipment and materials:

Ramina

Toyo

Andritz

Lenzing

Toray

Marzoli

Also

engineers of the

Cotton Club Group

Specifically for the needs of the Company, has developed 3DwaveIron, a unit of equipment designed to impart certain properties to the fabric (smoothness, additional tensile strength), and Doublecore, a dual absorbent layer forming unit which is installed on the diaper production line.

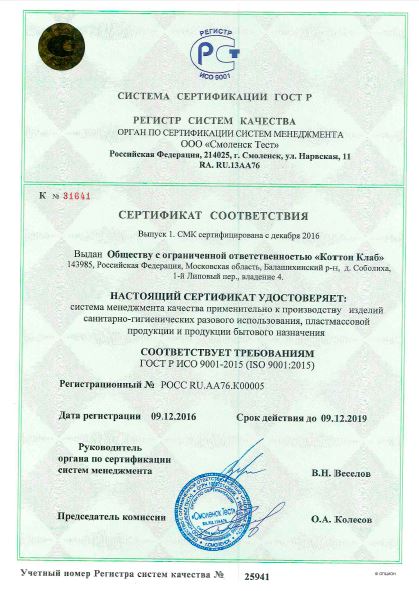

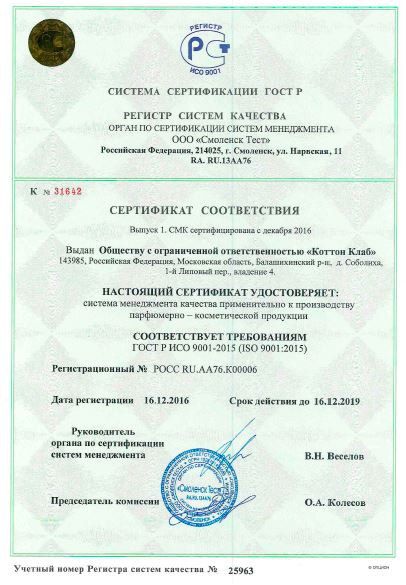

Certificates

Compliance with the requirements of ISO 9001 indicates the level of reliability of the supplier and the quality of his company.